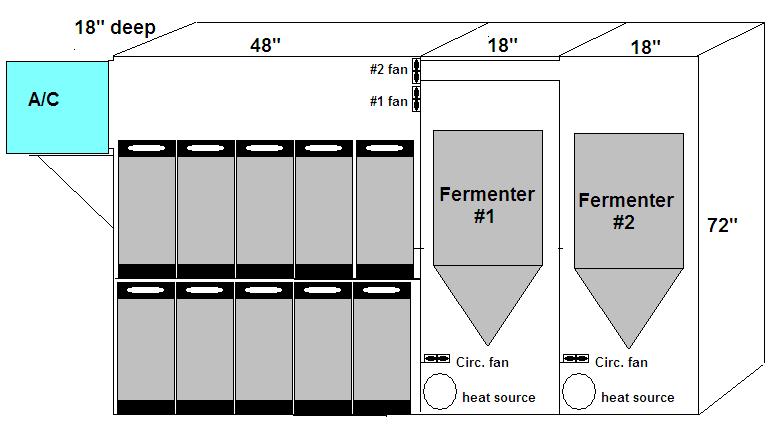

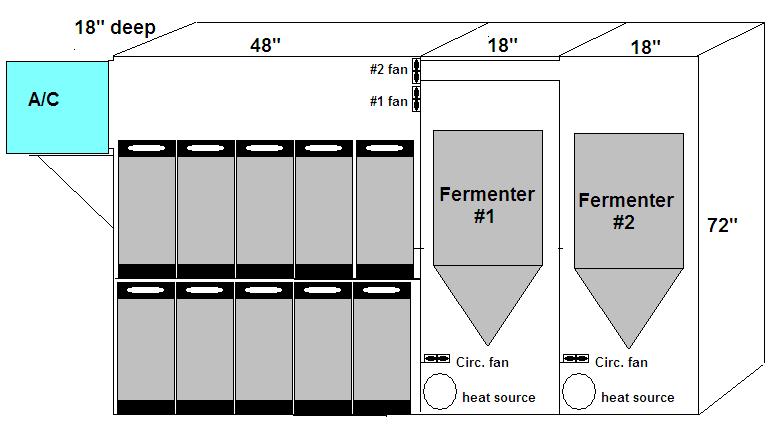

So the idea is that the first chamber on the left is the cold storage/lagering chamber, it will be temp controlled at ~35-40 (pretty much as low as I can get it) and be able to store at least 20 cornies. I'm also thinking if I can get the whole thing down into the 30's, I can use the cold chamber for serving as well. The two fermentation chambers will be connected to the cold chamber and the temperatures can be controlled independently by using fans to force the cold air to the ferment chamber. I also have heating elements in each of the fermentation chambers. My basement can get below 50 in the winter, so I want the option to be able to heat the chambers. I also want to be able to get each of the fermentation chambers just as cold as the main chamber so I can cold crash in the fermenter. Of course, the key to this system is outstanding insulation, thermal breaks in the design and keeping everything perfectly sealed. Otherwise, I won't be able to get the temp down low enough. I have access to unlimited, free, high performance insulation, so this thing is going to be crazy insulated. The insulation I'm going to use is R8/inch (the best foam you can get at your local building supply store is R6.5/inch) and I'll probably go with at least 2" thickness, maybe up to 3.5".So, that's that.

So the idea is that the first chamber on the left is the cold storage/lagering chamber, it will be temp controlled at ~35-40 (pretty much as low as I can get it) and be able to store at least 20 cornies. I'm also thinking if I can get the whole thing down into the 30's, I can use the cold chamber for serving as well. The two fermentation chambers will be connected to the cold chamber and the temperatures can be controlled independently by using fans to force the cold air to the ferment chamber. I also have heating elements in each of the fermentation chambers. My basement can get below 50 in the winter, so I want the option to be able to heat the chambers. I also want to be able to get each of the fermentation chambers just as cold as the main chamber so I can cold crash in the fermenter. Of course, the key to this system is outstanding insulation, thermal breaks in the design and keeping everything perfectly sealed. Otherwise, I won't be able to get the temp down low enough. I have access to unlimited, free, high performance insulation, so this thing is going to be crazy insulated. The insulation I'm going to use is R8/inch (the best foam you can get at your local building supply store is R6.5/inch) and I'll probably go with at least 2" thickness, maybe up to 3.5".So, that's that.

A crude drawing of my future cold storage/ferment chamber

#1

Posted 03 September 2009 - 09:03 PM

So the idea is that the first chamber on the left is the cold storage/lagering chamber, it will be temp controlled at ~35-40 (pretty much as low as I can get it) and be able to store at least 20 cornies. I'm also thinking if I can get the whole thing down into the 30's, I can use the cold chamber for serving as well. The two fermentation chambers will be connected to the cold chamber and the temperatures can be controlled independently by using fans to force the cold air to the ferment chamber. I also have heating elements in each of the fermentation chambers. My basement can get below 50 in the winter, so I want the option to be able to heat the chambers. I also want to be able to get each of the fermentation chambers just as cold as the main chamber so I can cold crash in the fermenter. Of course, the key to this system is outstanding insulation, thermal breaks in the design and keeping everything perfectly sealed. Otherwise, I won't be able to get the temp down low enough. I have access to unlimited, free, high performance insulation, so this thing is going to be crazy insulated. The insulation I'm going to use is R8/inch (the best foam you can get at your local building supply store is R6.5/inch) and I'll probably go with at least 2" thickness, maybe up to 3.5".So, that's that.

So the idea is that the first chamber on the left is the cold storage/lagering chamber, it will be temp controlled at ~35-40 (pretty much as low as I can get it) and be able to store at least 20 cornies. I'm also thinking if I can get the whole thing down into the 30's, I can use the cold chamber for serving as well. The two fermentation chambers will be connected to the cold chamber and the temperatures can be controlled independently by using fans to force the cold air to the ferment chamber. I also have heating elements in each of the fermentation chambers. My basement can get below 50 in the winter, so I want the option to be able to heat the chambers. I also want to be able to get each of the fermentation chambers just as cold as the main chamber so I can cold crash in the fermenter. Of course, the key to this system is outstanding insulation, thermal breaks in the design and keeping everything perfectly sealed. Otherwise, I won't be able to get the temp down low enough. I have access to unlimited, free, high performance insulation, so this thing is going to be crazy insulated. The insulation I'm going to use is R8/inch (the best foam you can get at your local building supply store is R6.5/inch) and I'll probably go with at least 2" thickness, maybe up to 3.5".So, that's that.

#2

Posted 03 September 2009 - 09:38 PM

#3

Posted 04 September 2009 - 02:52 AM

#4

Posted 04 September 2009 - 06:37 AM

Not if I want to keep my job.Nice! Any chance you can send me some of that insulation?

Good point. I may or may not have considered that, but I didn't think of it while I was making the drawing.A couple of questions/comments- Do you have air returns for each of the ferment chambers? You'll need a return to get enough airflow to control the temperatures.

That was my original design, but then I realized I would have to plan ahead to make sure I had the higher temp fermenter in chamber 1. Planning ahead isn't my strong suit.It may be easier to have air flow from ferment chamber 1 to chamber 2, rather than all the way from the cold box. You can still control them independently, but fermenter #2 will have to be the same temp or warmer than #1.

Yes on the louvers and probably yes on the 2x4 construction. My original design used 2" EPS foam as the structural members (the insulation i'm using is in granular form, so it isn't self supporting). 2x4s have about 5 times the thermal conductivity of the EPS, but if I'm upping the wall thickness from 2" to 3.5" that probably wouldn't matter since the overall heat load would be lower, even with the high conductivity wood structure.You may want to add louvers or some other way to block the airflow, so that when you are running the heater you aren't heating up the cold box.If you can get all the insulation you want, make the walls 3 1/2 inches- the width of a 2 x 4.

I am kind of space limited, but I haven't done all the measurements yet. I don't want it to be too cramped in there, but i also don't want it taking up too much space.Are you making it long and narrow to fit in a certain spot? If you can make it more square, you'll have less wall per the same area. Also, you should make it a bit wider than 2 cornies so you'll still have good airflow when it's full. Can you increase it to 24" wide?

Well, that's good to know. I was alittle worried about the cooling load, but from what you're saying it seems very doable.You should have no problem keeping it as cold as you want. I'd definitely use it for serving. I'm running a 5000 BTU window AC on my cold box, which is a 48" cube. The insulation is probably not as good as what you can get with the foam (it's framed 2x4s with regular roll fiberglass), and judging by the condensation it has some air leaks. I keep it set at 40F now, but it will go into the 20s if I crank it up. I'm using the AC's thermostat, so it did just that while I was dialing it in, tweaking the set screw on the thermostat to find the right temperature range.

#5

Posted 04 September 2009 - 06:44 AM

#6

Posted 04 September 2009 - 06:56 AM

#7

Posted 04 September 2009 - 07:04 AM

FAILflikr blocked at work - booooo

#8

Posted 04 September 2009 - 07:06 AM

Oooh, you're clever. I may have to think about this.Although, slapping a 100W light bulb into the chamber is pretty easy.Nice concept, it should work well. I wonder if there is a practical way to use the warm exhaust from the A/C unit to heat up the fermentation chambers in the winter, to save on operating costs. If the ambient temp is 50 F, then the holding chamber should still demand some run time from the A/C, so a dampered duct from the A/C hot side to the fermentation chamber could conserve some of the rejected heat.

#9

Posted 04 September 2009 - 08:39 AM

But the heat exhaust is dependent upon the unit actually running, which it may not do as much in the winter. If your insulation is that effective, your AC won't be running as much, which equals less residual heat from the unit, right? I'm just thinking it won't be a consistent heat and I think you want something that would be more constant and controlled. I say stick with the original plan. BTW, while it is clearly not AutoCad, it is far from crude! Nice job.Oooh, you're clever. I may have to think about this.Although, slapping a 100W light bulb into the chamber is pretty easy.

#10

Posted 04 September 2009 - 11:16 AM

Yeah, that's the problem. You need to be adding cold air to the main chamber to get warm air to the fermenting chambers. If you're fermenting two Saisons (that would be awesome), you'll might end up with frozen kegs.But the heat exhaust is dependent upon the unit actually running, which it may not do as much in the winter. If your insulation is that effective, your AC won't be running as much, which equals less residual heat from the unit, right? I'm just thinking it won't be a consistent heat and I think you want something that would be more constant and controlled. I say stick with the original plan. BTW, while it is clearly not AutoCad, it is far from crude! Nice job.

#11

Posted 04 September 2009 - 12:19 PM

You for sure wouldn't want to use the A/C warm exhaust for the primary means for heating the fermenting chambers, for the reason you guys mention. My thought was that warm air could be used whenever it was needed and available, as a supplement to your electrical resistance heating. The control mechanism could be that a damper in the exhaust duct opens to the fermenting chambers whenever its temperature is below its setpoint, simultaneously as you turn on your heating light bulb. The idea is that if warm air is available at that time, then the bulb would not need to burn as long, and you would save electricity.However, as I think about the cost and trouble to add the extra duct and dampers, versus what you would save in electricity, it probably wouldn't be worth it. Oh well, just another crazy idea of mine that didn't pan out.Yeah, that's the problem. You need to be adding cold air to the main chamber to get warm air to the fermenting chambers. If you're fermenting two Saisons (that would be awesome), you'll might end up with frozen kegs.

#12

Posted 04 September 2009 - 01:07 PM

Don't worry, I could fill the Library of Congress with my ideas that never panned out.Oh well, just another crazy idea of mine that didn't pan out.

#13

Posted 10 September 2009 - 02:29 PM

www.peekatwork.comflikr blocked at work - booooo

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users