That's a lot of hose! Is there a spot in the basement that is close to the garage wall? Can you feed the hose down through a wall and have it come out in the basement? I guess I'm thinking that you could position your kettle and the fermenter so that it's just running the vertical distance for the most part. You might be able to get away with 10 to 15 feet of hose, which I don't think is bad. And given, as you stated, that it's almost all "downhill" you shouldn't have too much dead space. IIRC, most specs for pumps are on a level ground.Thanks for all the input!If I go this route, I'll definitely be looking at a pump. Lugging around that much weight is not going to be an option.Something just occurred to me... If I brew in my garage and want to ferment in the basement, would there be any reason why I couldn't run a really long length of hose from kettle to fermenter in the basement with a pump? Will the length the liquid have to travel effect the type or power of pump you'd need? There would be some amount of gravity working for me...

Brute Can As Fermenter

#21

Posted 23 July 2009 - 04:13 PM

#22

Posted 23 July 2009 - 04:58 PM

#23

Posted 23 July 2009 - 04:59 PM

I have a feeling a lot more thinking/planning/plotting will be involved with this project before I start buying supplies. Thanks for the input yalls.That's a lot of hose! Is there a spot in the basement that is close to the garage wall? Can you feed the hose down through a wall and have it come out in the basement? I guess I'm thinking that you could position your kettle and the fermenter so that it's just running the vertical distance for the most part. You might be able to get away with 10 to 15 feet of hose, which I don't think is bad. And given, as you stated, that it's almost all "downhill" you shouldn't have too much dead space. IIRC, most specs for pumps are on a level ground.

#24

*_Guest_Blktre_*

*_Guest_Blktre_*

Posted 23 July 2009 - 05:17 PM

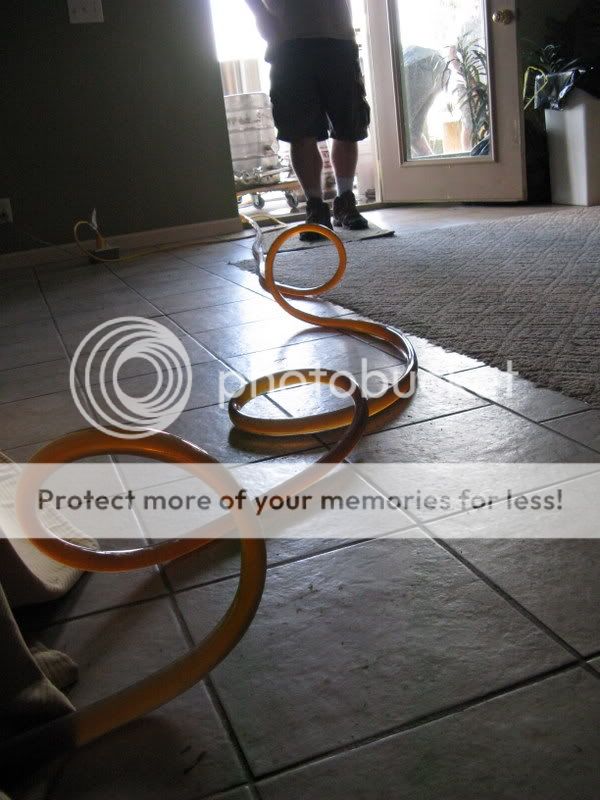

Through my basement using 1" tubing..

Through my basement using 1" tubing.. And into a pair of these....

And into a pair of these.... Probably alot more HP than a March I suspect.

Probably alot more HP than a March I suspect.

#25

Posted 23 July 2009 - 05:31 PM

I brew on the second floor porch of my house and ferment in my basement. I use 100 feet of high-temperature tubing, and a pure gravity feed. Well, I bought 100 feet of tubing, but then I cut off some of it, so I'm not sure how long it really is.The only issue I can see is that it can be hard to clean really long tubing. I have a sort of kluged contraption with a short piece of copper pipe that fits in the tube and makes it wide enough to seal on the inside of a faucet, and I use that to flush the tubing clean of beer. I sanitize by coiling the tubing up and putting it in a pot with water that I boil on the stove.If I brew in my garage and want to ferment in the basement, would there be any reason why I couldn't run a really long length of hose from kettle to fermenter in the basement with a pump? Will the length the liquid have to travel effect the type or power of pump you'd need? There would be some amount of gravity working for me...

#26

Posted 24 July 2009 - 05:49 AM

Check out the pumps at morebeer and williams brewing. They have pumps that are NOT rated to pump boiling/hot liquids, but designed to move liquids with minimum affect. Double check the web sites and confirm what I say.There are peristalic (SP?) pumps. You can find tem on ebay. They work by squeezing a hunk of rubber tubing. Interesting devices and usually expensive. But if you get lucky, you might find what you want. zymotIs it the march pump specifically or is there something against pumping fermented beer altogether?

#27

Posted 24 July 2009 - 05:17 PM

#28

Posted 25 July 2009 - 06:40 AM

#29

Posted 25 July 2009 - 08:31 PM

#30

Posted 25 July 2009 - 08:52 PM

fixed the linkLDPE linersI remember someone using a plastic liner. Maybe something like this ??16 Micron x 43" x 48" HDPE Liners

Edited by Cliff Claven, 25 July 2009 - 09:02 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users