Stir plate

#1

Posted 04 August 2010 - 09:40 PM

#2

Posted 05 August 2010 - 04:46 AM

#3

Posted 05 August 2010 - 06:47 AM

#4

Posted 05 August 2010 - 07:19 AM

I don't think it'd be the same as a starter cap on a ac motor. I'm thinking of it as a way to provide more initial current to start. Though I'm not sure it would work. The caps in the power supply should be fully charged, and apparently that's not enough to get it moving on it's own. Maybe the magnet is just too much for the wimpy fan. I could dig through my junk and try to find a higher current AC/DC converter. As it is currently set up, there's no series resistance other than what's in the converter and wiring. A switch might help, vs putting the wire in the breadboard hole. I'll screw around with it, see if anything works.It kept 3L spinning throughout the night, so I'm pretty confident it'll work. The vortex was pretty constant, every now and then it would touch the stir bar and "bounce" back up. That was at 7.5V. 6V seemed to provide a wimpy vortex. Higher than 7.5 and it would jump out of the field.I may be wrong - it's been decades since I had motor theory - but I don't think that a DC motor benefits from a starting capacitor. IIRC, only AC motors with specially-made starter stator circuits need starter caps.

#5

Posted 05 August 2010 - 02:17 PM

#6

Posted 09 August 2010 - 08:10 AM

#7

Posted 09 August 2010 - 08:25 AM

I've asked that question a few times. I let it go until it's done. After using it several times it became obvious to me when major activity was done - krausen drop, steady color - no real bubble activity when you turn it off for a minute or two.I'd say on average if I use an Activator pack it'll finish in 1 - 2 days. Maybe a day longer using a Propagator. That's usually around 2.5L for most ales.How long do you guys let your stir plate starters go for before chilling them and pouring off the non-yeast part?

#8

Posted 10 August 2010 - 04:59 PM

A link if the above pictiure is dodgy.

A link if the above pictiure is dodgy.

#9

Posted 10 August 2010 - 07:41 PM

Today was a classic example. I smacked an Activator pack of 1007, notorious top cropper, last night and pitched it directly into a starter. 2.25L starter in a 4L flask. Krausen had dropped from an obvious max of about 3.5L even with some Fermcap in it. It was opaque and darker from the yeast early this morning and dropped the krausen some by tonight. Still has a liter of foam but seeing it drop let me know it's not too soon to chill it. Hope that helps.Actually, I was surprised. The yeast was a couple months old when I opened it. You never know............. ETA, on the stirplate which made a difference..........How long do you guys let your stir plate starters go for before chilling them and pouring off the non-yeast part?

Edited by djinkc, 10 August 2010 - 07:42 PM.

#10

Posted 11 August 2010 - 09:47 AM

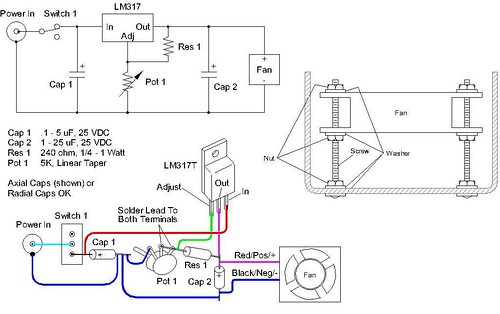

It's not worth it to me to put that much effort into it, as it currently works. I'm going to change the power supply, because I need my variable one for other tinkering. I might just find one that can output more current. The only thing I'd be willing to pay for is a potentiometer if I cant rip one out of something else I have in the electronic junk bin. I can wire that to the power input, no need for a voltage regulator. It's a fan, it doenst require ultra clean power.If you put the switch between the cap and the fan, First charged the cap (by applying DC) and then flipped the switch, you might get a bonus surge of current to kick start the fan. For a short period, it would be like having two power supplies in parallel to dump current into the fan.This is as much a hypothetical model as it might be in world world application. Depends on the output impedance of your the power supply you are using and the ESR characteristic of the cap you are using. Electronics hobbiest nerd talk for may work, may not.If you put the switch before the cap such that when you flip the switch you have the cap and the fan seeing voltage at the same instant, the cap could be detrimental to your cause. In that case, you are splitting the power supply into doing 2 jobs. 1 - getting the fan to start spinning & 2 - charging the cap. Once the cap is charged, then it's only purpose is to smooth and AC voltage component of the DC.What will work best is a low output impedance variable power supply using the common LM337T voltage regulator. All the parts can be bought at Radio Shack. Here is a proven design.

A link if the above pictiure is dodgy.

#11

Posted 11 August 2010 - 09:57 AM

Until it stops fermenting.How long do you guys let your stir plate starters go for before chilling them and pouring off the non-yeast part?

#12

Posted 11 August 2010 - 12:38 PM

I am the first to say if something works and you are happy with it, stop messing with it and go make some beer.The regulator design is not for ultra clean power. The regulator is create a 0-12 VDC supply (easily adjusted with a knob) to make controlling the fan very simple and predictable.When you get put a potentiometer between the power supply and the fan, you are adding variables that are not as obvious and could give hit or miss sketchy results.The design I show, works and will work with any 12 VDC muffin fan. Basically it overcomes the variables that are introduced by the simple potentiometer designs.It's not worth it to me to put that much effort into it, as it currently works. I'm going to change the power supply, because I need my variable one for other tinkering. I might just find one that can output more current. The only thing I'd be willing to pay for is a potentiometer if I cant rip one out of something else I have in the electronic junk bin. I can wire that to the power input, no need for a voltage regulator. It's a fan, it doenst require ultra clean power.

#13

Posted 11 August 2010 - 04:22 PM

The pot straight off the +12V line would essentially do the same thing as the pot with the regulator. The only difference is the pot in the regulator circuit is controlling the output of the regulator and draws minimal current while the pot in the no-reg circuit actually dissipates power. I suspect I'd need a pot that wont burn up to do it the cheapo way. Just a swag at the power yields ~5W. I may have a 1/4W or 1/2W one lying around, but not >5W. I'm not knockin your circuit, it just seems "too good" for the application.I am the first to say if something works and you are happy with it, stop messing with it and go make some beer.The regulator design is not for ultra clean power. The regulator is create a 0-12 VDC supply (easily adjusted with a knob) to make controlling the fan very simple and predictable.When you get put a potentiometer between the power supply and the fan, you are adding variables that are not as obvious and could give hit or miss sketchy results.The design I show, works and will work with any 12 VDC muffin fan. Basically it overcomes the variables that are introduced by the simple potentiometer designs.

#14

Posted 11 August 2010 - 04:34 PM

I think you should try a different fan. I almost built Zymot's design (nice btw) but mine works fine with the wall wort I use. I've never had reason to adjust the speed, it just works.The pot straight off the +12V line would essentially do the same thing as the pot with the regulator. The only difference is the pot in the regulator circuit is controlling the output of the regulator and draws minimal current while the pot in the no-reg circuit actually dissipates power. I suspect I'd need a pot that wont burn up to do it the cheapo way. Just a swag at the power yields ~5W. I may have a 1/4W or 1/2W one lying around, but not >5W. I'm not knockin your circuit, it just seems "too good" for the application.

#15

Posted 11 August 2010 - 04:53 PM

that is correct. for me I basically wait until I don't see any signs of fermentation for half a day. Normally it takes about 1-2 days for the job to complete. Depends how much yeast, how big the starter is, how healthy the yeast is, etc.Until it stops fermenting.

#16

Posted 11 August 2010 - 06:32 PM

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users