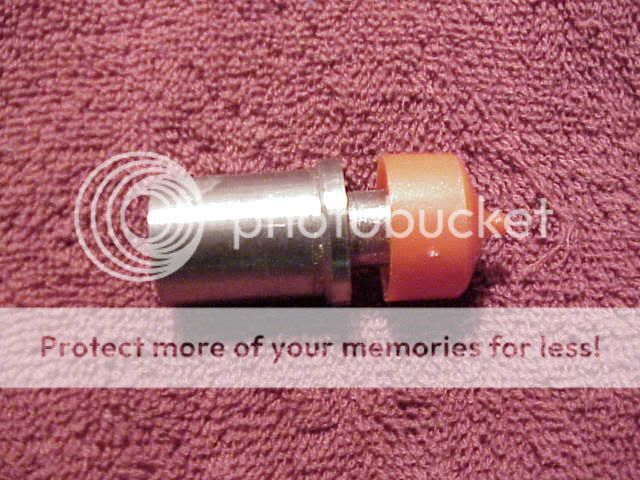

This one is a custom length and the inner tube had not been bent to a 90 degree.

This one is a custom length and the inner tube had not been bent to a 90 degree. showing flow thru a 1/2 plastic tubingDoes take a bit of lathe work and each is a custom fit from piston to outer tube.May God BlessSwagman

showing flow thru a 1/2 plastic tubingDoes take a bit of lathe work and each is a custom fit from piston to outer tube.May God BlessSwagman

Posted 28 December 2011 - 04:32 PM

This one is a custom length and the inner tube had not been bent to a 90 degree.

This one is a custom length and the inner tube had not been bent to a 90 degree. showing flow thru a 1/2 plastic tubingDoes take a bit of lathe work and each is a custom fit from piston to outer tube.May God BlessSwagman

showing flow thru a 1/2 plastic tubingDoes take a bit of lathe work and each is a custom fit from piston to outer tube.May God BlessSwagman

Posted 28 December 2011 - 04:36 PM

Posted 29 December 2011 - 09:26 AM

Edited by BlKtRe, 29 December 2011 - 09:27 AM.

Posted 29 December 2011 - 09:31 AM

WANT!I have broken so many auto siphons. The last one cut me up pretty good too :stabby:SwagmanHad a brewer come to the shed the other day asking me to make a Stainless steel siphon . I had made one a few years ago just for kicks to see if one could be. At that time I figured no one would want one. Here is what I came up for the brewer who had broke 5 plastic ones the last two years. The output is thru a 1/2 ss tubing makes transfer a little faster.Has two check valves one in the tip the other in the piston that is a part of the inner tube.

This one is a custom length and the inner tube had not been bent to a 90 degree.

showing flow thru a 1/2 plastic tubingDoes take a bit of lathe work and each is a custom fit from piston to outer tube.May God BlessSwagman

Posted 29 December 2011 - 10:20 AM

Posted 29 December 2011 - 10:27 AM

Posted 29 December 2011 - 11:37 AM

Posted 29 December 2011 - 11:42 AM

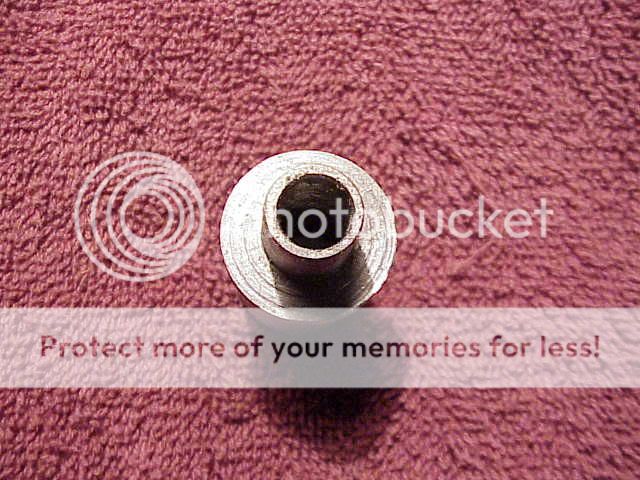

I'll try when the inner 1/2 tube is pulled up the check valve in it closes and the check valve in the outer tube opens pulling liquid in. When the inner tube is push down the inner tube check valve opens letting liquid to flow up and out, the outer tube check valve close's and than reopens when the siphon starts. The piston holds the check valve plus holds the o-ring that seals to outer tube. The outer check valve is contain in the tip. All parts are silver soldered together makes for easy disassemble if need. The inside of the 1 inch tube and not quite the same so each piston is custom fitter to the tube. I know clear as mud lol but it works and can move 5 five gallons in about 3 minutes. May God BlessSwagmanMarty,Can you explain more about the check valves and piston please? Does the piston help start a siphon like one of those plastic auto-siphon sold online? And obviously the check valves hold the siphon so it wont need to be primed again.

Posted 29 December 2011 - 11:50 AM

Posted 29 December 2011 - 12:08 PM

Posted 29 December 2011 - 01:51 PM

Posted 29 December 2011 - 02:53 PM

Posted 29 December 2011 - 03:07 PM

I second that. And he lives just a 40min ride from me....Been awhile since I made a visit.Swagman really outdid himself on this gadget.

Edited by BlKtRe, 29 December 2011 - 03:08 PM.

Posted 30 December 2011 - 09:11 AM

Posted 30 December 2011 - 10:45 AM

Posted 30 December 2011 - 10:48 AM

Posted 30 December 2011 - 02:40 PM

Posted 30 December 2011 - 08:29 PM

Posted 31 December 2011 - 01:05 PM

Here is Engineer change number one better known as the Schilling change. The tip is now a part of the outer tube check valve, eliminates a solder joint which might a weak point. Takes more material and a bit more lathe time.Each one is a custom fit when comes to the piston. With material cost and not charging shop cost and doing what I can to keep the cost down I'm going to ask 55.00 plus shipping. But with the other irons in the fire I'm also going to limit the build to three a month if it gets to that point. Being retired I keep asking myself when did I have time to work.Had a brewer come to the shed the other day asking me to make a Stainless steel siphon . I had made one a few years ago just for kicks to see if one could be. At that time I figured no one would want one. Here is what I came up for the brewer who had broke 5 plastic ones the last two years. The output is thru a 1/2 ss tubing makes transfer a little faster.Has two check valves one in the tip the other in the piston that is a part of the inner tube.

This one is a custom length and the inner tube had not been bent to a 90 degree.

showing flow thru a 1/2 plastic tubingDoes take a bit of lathe work and each is a custom fit from piston to outer tube.May God BlessSwagman

May God BlessSwagman

May God BlessSwagman

Posted 31 December 2011 - 01:33 PM

0 members, 1 guests, 0 anonymous users