Anvil Foundry system

#1

Posted 16 August 2020 - 11:16 AM

#2

Posted 16 August 2020 - 01:36 PM

#3

Posted 17 August 2020 - 01:06 PM

#5

Posted 22 August 2020 - 03:46 PM

I have the 6.5 Gallon Anvil Foundry, which brews 2.5-3 Gallon batches. I'm running it on 120V (can be changed to 240v by changing the plug and flipping a switch.)

So far I've brewed 1 batch of Irish Stout.

My gravity came out low, so I had to add some DME at the end. The process went very smoothly. It's very easy to use.

I'm going to try the following to improve my efficiency:

1. Crush the grain twice.

2. Use a Wilser bag.

3. Stir more during the mash (I only raked the top 1/3 or so).

4. Circulate much more slowly during the mash.

5. Boil a little more vigorously (I had turned the power down during the boil and my volume came out a bit high)

Other changes I've made:

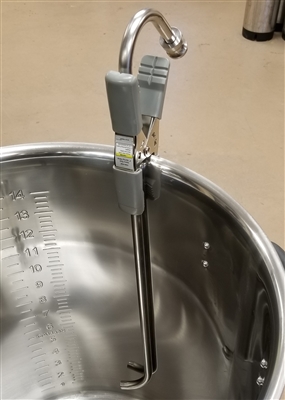

The stainless steel immersion chiller that comes with the unit is only about half submerged. So, I bought one of these:

https://www.nybrewsu...ant=42199963476

It fits perfectly and I think it will work much better. I may use the old chiller as a pre-chiller in a bucket of ice water.

I also got one of these to whirlpool:

https://www.brewhard...leoverboard.htm

I got mine with a welded cam lock fitting, and I also added a cam lock fitting to the Foundry's recirculation tube so I can swap the pump hose easily from mash to whirlpool.

The Anvil Foundry is a breeze to set up, tear down, clean, and store. The pump works great and is easy to clean.

Brew #2 will probably be tomorrow or Monday. I'm thinking a West Coast IPA.

I'll also keg the stout tomorrow. I just got 4 - 3 Gallon kegs and got a full 5# tank of CO2.

Edited by jimdkc, 22 August 2020 - 03:55 PM.

#6

Posted 23 August 2020 - 03:52 AM

What exactly was your efficiency? I was thinking of aiming for a ~7% beer on my first brew so if efficiency is lower than expected I can just add less hops and have a lower abv beer.

#7

Posted 23 August 2020 - 12:21 PM

I was aiming for 1.049 OG with the recipe set at 70%. Got 1.038.

I think (hope!) the finer crush, Wilser bag, and slower recirculation will correct this.

#8

Posted 23 August 2020 - 02:12 PM

#9

Posted 23 August 2020 - 02:26 PM

#10

Posted 23 August 2020 - 03:14 PM

#11

Posted 31 August 2020 - 08:39 PM

I will be doing this on 120 volt to start with until I figure out a bridging temporary solution (making the dryer outlet GFCI and running an extension to the garage), or the longer term solution (which is a dedicated 240 volt GFCI located in my future brew kitchen off the laundry room) becomes possible. My 120 volt garage outlet is GFCI.

Edited by porter, 31 August 2020 - 08:56 PM.

#12

Posted 01 September 2020 - 04:14 AM

Ok, I was officially gifted the brewing rig, unpacked it, will likely do the first brew the weekend after Labor Day weekend. It looks nice. The chiller looks just the right size to me. I wonder if they used the same size chiller for both the smaller and larger version (I have the larger version)?

I will be doing this on 120 volt to start with until I figure out a bridging temporary solution (making the dryer outlet GFCI and running an extension to the garage), or the longer term solution (which is a dedicated 240 volt GFCI located in my future brew kitchen off the laundry room) becomes possible. My 120 volt garage outlet is GFCI.

On version 3 of my electric rig I had build up an GFCI extension cord. That worked well and I did trip it once with a dry fire so that is something to look into.

#13

Posted 01 September 2020 - 11:34 AM

I think I'll just stick with 120 volt for now and then hire an electrician to put in a dedicated outlet and GFCI breaker when the space for my brew kitchen becomes available.

We have a few other electrical projects to be done, so hiring an electrician would make sense.

Whoops, and that was 120 volt. I'd have to buy one of those in line GFCI breakers which are 2 feet and then add an extension cord. I'll do light fixtures and outlets but don't feel comfortable working on the panel. It would probably be not much more expensive to get a GFCI breaker installed by an electrician.

https://www.gordonel...an-Gfci/6046285

Edited by porter, 01 September 2020 - 11:38 AM.

#14

Posted 01 September 2020 - 01:04 PM

#15

Posted 01 September 2020 - 01:12 PM

Reuse the 220v extension cord for both.

#16

Posted 01 September 2020 - 01:24 PM

Looks like $$$ to get what I need: https://www.ebay.com...AgAAOSwNlVefhrU

I think I'll just stick with 120 volt for now and then hire an electrician to put in a dedicated outlet and GFCI breaker when the space for my brew kitchen becomes available.

We have a few other electrical projects to be done, so hiring an electrician would make sense.

Whoops, and that was 120 volt. I'd have to buy one of those in line GFCI breakers which are 2 feet and then add an extension cord. I'll do light fixtures and outlets but don't feel comfortable working on the panel. It would probably be not much more expensive to get a GFCI breaker installed by an electrician.

https://www.gordonel...an-Gfci/6046285

Pay shipping and you can have it.

#17

Posted 01 September 2020 - 06:12 PM

So these Anvil systems have two plugs on them, one for 120v and one for 240v?

They come with a 120V plug. You change the plug to a 240V plug and flip a switch (under a metal plate) to change the voltage.

#18

Posted 01 September 2020 - 09:07 PM

Looks like $$$ to get what I need: https://www.ebay.com...AgAAOSwNlVefhrU

I think I'll just stick with 120 volt for now and then hire an electrician to put in a dedicated outlet and GFCI breaker when the space for my brew kitchen becomes available.

We have a few other electrical projects to be done, so hiring an electrician would make sense.

Whoops, and that was 120 volt. I'd have to buy one of those in line GFCI breakers which are 2 feet and then add an extension cord. I'll do light fixtures and outlets but don't feel comfortable working on the panel. It would probably be not much more expensive to get a GFCI breaker installed by an electrician.

https://www.gordonel...an-Gfci/6046285

Do not overlook the need for ventilation and moving air in, through and out of the brew space. Any savings you gain with an easy AC upgrade could get offset by the requirement of installing an adequate exhaust fan and vent.

First place to consider is near your AC breaker box. If you put in a 240 VAC GFCI and a 120 VAC GFCI circuit near breaker panel, what kind of brewing space would you have?

#19

Posted 01 September 2020 - 10:06 PM

Ok, I was officially gifted the brewing rig, unpacked it, will likely do the first brew the weekend after Labor Day weekend. It looks nice. The chiller looks just the right size to me. I wonder if they used the same size chiller for both the smaller and larger version (I have the larger version)?

The immersion chiller that comes with the 10 gallon system is apparently bigger than the one that comes with the 6.5 gallon system that I have:

10 Gallon:

6.5 Gallon:

This thing's only half-way into the wort when you hang it over the edge of the kettle.

The one I bought from NY Brew Supply (pictured in my post above) goes all the way to the bottom.

Edited by jimdkc, 01 September 2020 - 10:09 PM.

#20

Posted 02 September 2020 - 05:26 AM

I was kind of excited for a second when I thought you could buy a 10 gal system like this for under $400 but then I realized that is to yield 5 gallons ![]()

Still a nice looking rig at a reasonable price though.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users