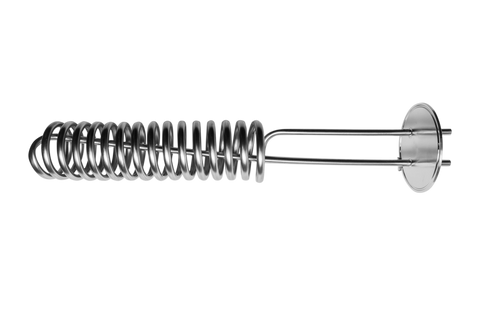

Yes, I have all of those on a 1.5" tri-clamp cover. You should be able to fit your 3 on a 3" with out much problem. I think your thought with the three tubes should be fine. If it was me, I would have the one for the airlock/blowoff threaded so you could add a valve to close it up. But that is not necessary. Alternatively, you could get a weld-less tri-clamp adapter and put that on the cover and use that for the blowoff.

Spike does a similar thing but they have a 4" tri-clamp cover