Main components are as follows:Auber Universal 1/16 DIN PID Temperature Controller - linkAuber Liquid tight RTD sensor x 2 - linkAuber multifunction timer, counter, tachometer - link1/4" Solenoid Valve x 3 (for pilots)1/2" Solenoid Valve x 3 (for main burner)Honeywell Q373A2115 Intermittent Pilot Burner Igniter x3 (I'm thinking I will manually fire these with switches - I'm not sure how to wire them to auto fire with the solenoids) I appreciate any guidance on this. I'm designing a 2 tier Brutus inspired system that will fit in my Honda Accord.

Main components are as follows:Auber Universal 1/16 DIN PID Temperature Controller - linkAuber Liquid tight RTD sensor x 2 - linkAuber multifunction timer, counter, tachometer - link1/4" Solenoid Valve x 3 (for pilots)1/2" Solenoid Valve x 3 (for main burner)Honeywell Q373A2115 Intermittent Pilot Burner Igniter x3 (I'm thinking I will manually fire these with switches - I'm not sure how to wire them to auto fire with the solenoids) I appreciate any guidance on this. I'm designing a 2 tier Brutus inspired system that will fit in my Honda Accord.

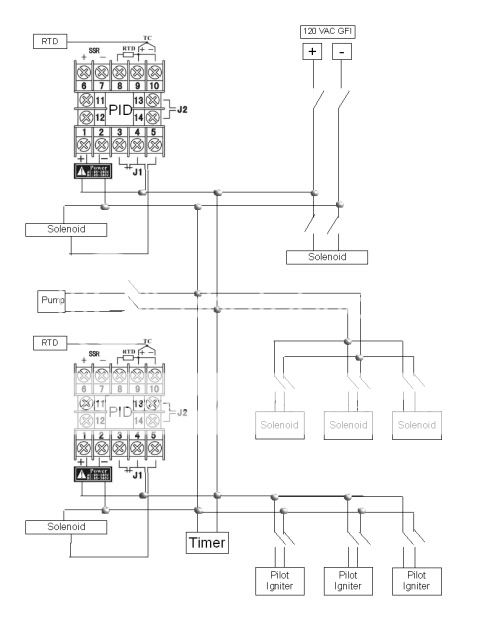

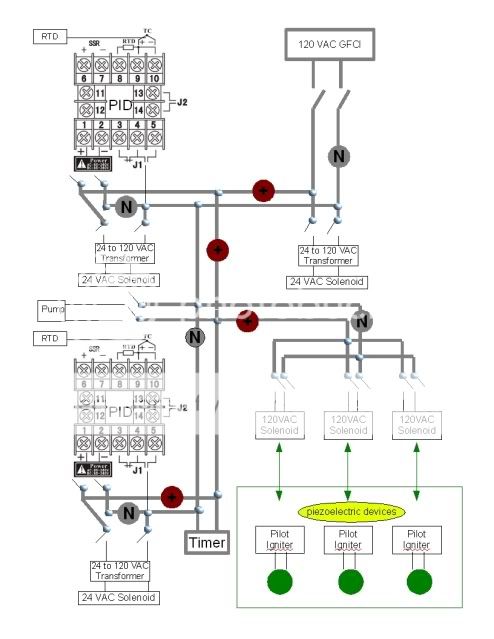

Does this wiring diagram look like it would work

#1

Posted 22 May 2010 - 12:53 PM

Main components are as follows:Auber Universal 1/16 DIN PID Temperature Controller - linkAuber Liquid tight RTD sensor x 2 - linkAuber multifunction timer, counter, tachometer - link1/4" Solenoid Valve x 3 (for pilots)1/2" Solenoid Valve x 3 (for main burner)Honeywell Q373A2115 Intermittent Pilot Burner Igniter x3 (I'm thinking I will manually fire these with switches - I'm not sure how to wire them to auto fire with the solenoids) I appreciate any guidance on this. I'm designing a 2 tier Brutus inspired system that will fit in my Honda Accord.

Main components are as follows:Auber Universal 1/16 DIN PID Temperature Controller - linkAuber Liquid tight RTD sensor x 2 - linkAuber multifunction timer, counter, tachometer - link1/4" Solenoid Valve x 3 (for pilots)1/2" Solenoid Valve x 3 (for main burner)Honeywell Q373A2115 Intermittent Pilot Burner Igniter x3 (I'm thinking I will manually fire these with switches - I'm not sure how to wire them to auto fire with the solenoids) I appreciate any guidance on this. I'm designing a 2 tier Brutus inspired system that will fit in my Honda Accord.

#2

Posted 22 May 2010 - 01:48 PM

#3

Posted 22 May 2010 - 02:28 PM

Thanks for the reply. I'm no expert, so any help is appreciated.It has been a few years since I specifically worked in the industrial controls business, but non of this makes any sense to me.

All of the devices are 120 VAC, so I assumed that would be the easiest way to get power to them all...is there a better way?You have 120 VAC going into something marked + & -. And you 120 VAC basically bussed to all the devices.

The solenoids are normally closed, and open when power is applied to them (don't they?). I planned to use manual toggle switches to complete the circuit and power the system/open the valve. When the circuit is complete, I'm thinking the PID will act to fire the burners based on the temperature reading of the RTD (the PID has an off/on setting). The PID will act as a relay to do this won't it? I'm I incorrect about this?You have switch symbols that control solenoids. No way to tell what makes the switches open and close. If these are relays, what makes the relays open and close?

This is true, I wanted a built in timer on the control panel to time my mash and hop additions. The only thing it will do is act as a timer, so all it needs is power right? This timer has more capability then my wiring skills, so some of that will be wasted in this application but I'm okay with that.As drawn, the timer does nothing other sitting on 120 VAC. What do you want the timer to do? It has no output.

The temp sensors will trigger the on/off set points of the PID and open close the solenoids connected to it (i think) If I'm off base please let me know. I'm doing the planning before I order the components and want to get this right the first time to prevent costly mistakes. Thanks a lot.Can provide a simple explanation for what you want each sensor to do?

#4

Posted 22 May 2010 - 02:44 PM

#5

Posted 22 May 2010 - 03:47 PM

#6

Posted 22 May 2010 - 04:57 PM

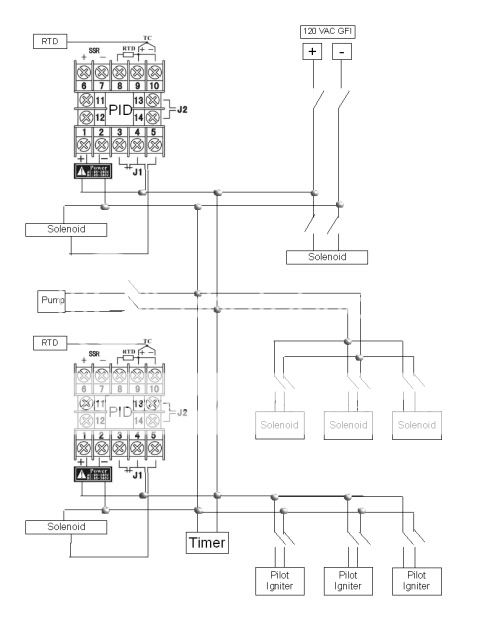

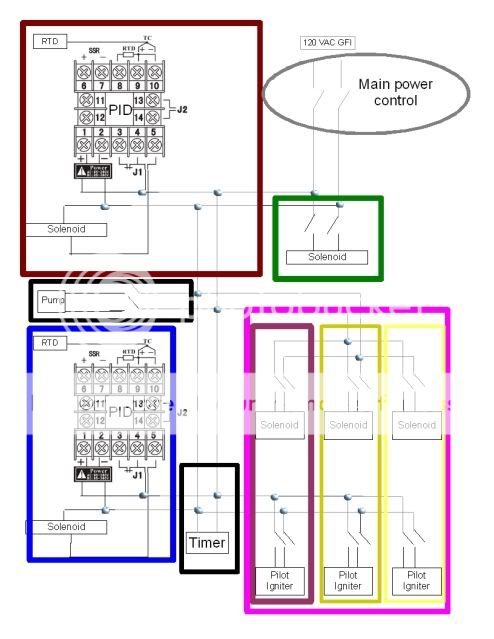

Are you implying that my main power trunk and zone thinking won't work? If so do you have any ideas to make this work?

Are you implying that my main power trunk and zone thinking won't work? If so do you have any ideas to make this work?

#7

Posted 22 May 2010 - 08:56 PM

#8

Posted 22 May 2010 - 10:26 PM

#9

Posted 23 May 2010 - 04:27 AM

#10

Posted 23 May 2010 - 06:05 AM

#11

Posted 23 May 2010 - 06:30 AM

#12

Posted 23 May 2010 - 06:58 AM

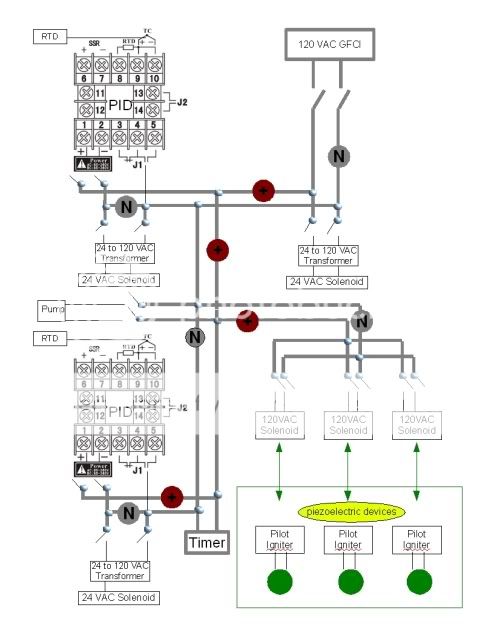

Thanks, that will save me a headache I didn't even think about looking into. Per Honeywell it needs 15,000V ... I ain't messing with that. The battery ignition systems from a grill was a backup plan I had in mind so I'll have to see if I can remove the high voltage ignition system and retofit the pilot assembly to hold it.Your pilot igniter will not work as drawn. The spark comes from a high voltage transformer or pilot controller, not 110 VAC.In industrial firing a flame rod, thermocouple or ultraviolet detector would be used to detect pilot flame to allow the main burner control to activate.The pilot device you have listed will supply a standing pilot once gas is applied and the gas is ignited.You could possibly use a gas grill push button piezoelectric device to generate your ignition spark since it is a manned firing device.

looking at the 2 images it doesn't seem like it will that hard.

looking at the 2 images it doesn't seem like it will that hard. I can't figure out how to do it with 1 switch (without a gas sensor that fires the spark ignition), so I settled on a 2 switch solution. I would like to avoid keeping standing pilots on all 3 burners the whole brew session, but during the mash the pilot will remain lit.I think what you have will work. I haven't worked with gas, but I'm wondering why you have your pilot gas and pilot ignitors on manual toggles? Do you leave the pilot gas and ignitor on the entire time you brew? Could you wire the pilot gas solenoid, ignitor and main gas line for each zone into one switch/relay so they always come on at the same time?

#13

Posted 23 May 2010 - 07:29 AM

It is hard to comment much more without knowing your planned workflow. All I can tell from the diagram you have 2 temp sensors that each one controls it's own solenoid. The solenoids will turn on and off depending on how you have the PID programmed. The other devices are under manual control.For the timer, it has relay outputs that open and close depending on the programming of the timer. You can use those rely to open or close (AKA tun on or turn off) a device based on a time interval(s). Looks as if you can add your own buttons for the Start, Pause, Reset function. I tend to like those over the membrane switch that typically come with these kinds of units. Plus buttons can look cool. You can also use the relay out put to work in combination with some other PID logic or one of your manual switches. Two switches can be wired two ways. Serial or parallel. This is the same serial and parallel you had with light bulbs, think old time Christmas tree lights.Wire 2 switches in serial, you must close both switches to energize a device. This creates a AND logic circuit. E.g. Switch #1 AND Switch #2 must be closed to energize Device X.Wire 2 switches in parallel, you can close either switch to energize the device. This creates an OR logic circuit. E.g. Switch #1 OR Switch #2 can be closed to energize Device X.Off hand I do not know how you might use this, but you got a nice $33.50 (plus shipping and handling) timer, maybe this will help you get some additional function from it.zymotThanks zymot ... I'll be ordering the components in the near future to see if it works in the "real world."EDIT: can you think of any other way that I could wire that timer to make better use of it's abilities?

#14

Posted 24 May 2010 - 12:08 PM

#15

Posted 24 May 2010 - 12:40 PM

The transformer can tap off the 120 VAC, like any other device. This will not affect the GFI, in fact it might lower the likely hood the GFI will trip. You need just 1 transformer for all the 24 VAC solenoids. This assumes the transformer selected has enough current to power 3 solenoids. It should be easy to locate such a transformer, and cheaper too.The switches you have for each solenoid would be on the 24 VAC side of the transformer would switch 24 VAC per each solenoid.I got 6 solenoids given to me from a friend who got them from me from work - they have Viton seals so should be good to go with LP. The three 1/2" solenoids that I would be using on the main burners are 24 VAC and the three 1/4" are 120 VAC. I just got them yesterday and noticed the voltage, so I'll have to rework the wiring to include some transformers. If I use a 120 VAC input / 24 VAC output transformer to step down the power supply for the solenoids do I have to do anything special on the neutral return before it hits the GFCI?

#16

Posted 24 May 2010 - 04:48 PM

the bold gray is what I'm calling the trunk line. I added switches going into the PIDs so I would be able to run the burners without the PID if I ever want to. Any all input is greatly appreciated!In other news I picked up $240 worth of steel for the stand today. I should start cutting and welding in a week. Went with cold rolled since I can't weld stainless on my system ... I'll start a construction thread when I get around to starting this.

the bold gray is what I'm calling the trunk line. I added switches going into the PIDs so I would be able to run the burners without the PID if I ever want to. Any all input is greatly appreciated!In other news I picked up $240 worth of steel for the stand today. I should start cutting and welding in a week. Went with cold rolled since I can't weld stainless on my system ... I'll start a construction thread when I get around to starting this.

#17

Posted 24 May 2010 - 05:15 PM

Double check how you have drawn the switches around to the 24 VAC transformer.With the right dot where it is, the both ends of the primary of the transformer will go to the N side of your trunk line. Nothing will happen. When the PID tuen on, short circuit, worse than nothing happens.If you move the right dot to the + side of you trunk line, you fix it so the the switch energizes the solenoid. But then your PID will do nothing. The only way the PID can work is if the switch is closed. If the switch is closed the solenoid is energized and the PID will turn on a previously energized solenoid, no change.Suggested fix. Do not switch the N side of trunk line into transformer. Use one side of the switch and put it in parallel with the PID output. This should create the "OR" typeof logic I think you are looking for.zymotThanks again. Here's working diagram v. 2.0.1

the bold gray is what I'm calling the trunk line. I added switches going into the PIDs so I would be able to run the burners without the PID if I ever want to. Any all input is greatly appreciated!

#18

Posted 24 May 2010 - 05:47 PM

you're right ... thanks! I was attempting to make everything fit and must of missed that. v. 2.0.2Double check how you have drawn the switches around to the 24 VAC transformer.With the right dot where it is, the both ends of the primary of the transformer will go to the N side of your trunk line. Nothing will happen. When the PID tuen on, short circuit, worse than nothing happens.If you move the right dot to the + side of you trunk line, you fix it so the the switch energizes the solenoid. But then your PID will do nothing. The only way the PID can work is if the switch is closed. If the switch is closed the solenoid is energized and the PID will turn on a previously energized solenoid, no change.Suggested fix. Do not switch the N side of trunk line into transformer. Use one side of the switch and put it in parallel with the PID output. This should create the "OR" typeof logic I think you are looking for.zymot

#19

Posted 24 May 2010 - 06:14 PM

I've been thinking about this, and I think I'll just wire in a buzzer to the timer ... everything else seems overly complicated for my application.For the timer, it has relay outputs that open and close depending on the programming of the timer. You can use those rely to open or close (AKA tun on or turn off) a device based on a time interval(s). Looks as if you can add your own buttons for the Start, Pause, Reset function. I tend to like those over the membrane switch that typically come with these kinds of units. Plus buttons can look cool. You can also use the relay out put to work in combination with some other PID logic or one of your manual switches. Two switches can be wired two ways. Serial or parallel. This is the same serial and parallel you had with light bulbs, think old time Christmas tree lights.Wire 2 switches in serial, you must close both switches to energize a device. This creates a AND logic circuit. E.g. Switch #1 AND Switch #2 must be closed to energize Device X.Wire 2 switches in parallel, you can close either switch to energize the device. This creates an OR logic circuit. E.g. Switch #1 OR Switch #2 can be closed to energize Device X.Off hand I do not know how you might use this, but you got a nice $33.50 (plus shipping and handling) timer, maybe this will help you get some additional function from it.zymot

#20

Posted 24 May 2010 - 11:01 PM

The PID/Solenoid/Switch still section is not correct. If you build it as shown, when the PID tries to energize the solenoid, it will short out your 120 VAC trunk lines.When I can get to a computer where I can draw a what I am tlaking about, I will show you what I mean.zymotyou're right ... thanks! I was attempting to make everything fit and must of missed that. v. 2.0.2

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users